服务热线

020-85250202

产品时间:2025-12-30 15:54

简要描述:

原装进口美国OMEGA传感器级应变计,三种样式:用于实验应力分析的单轴,用于轴向应变的扭转/剪切半桥堆叠,T型应变花,非常灵活,机械强度高,弯曲半径小,封装以增加耐用性,温度范围...

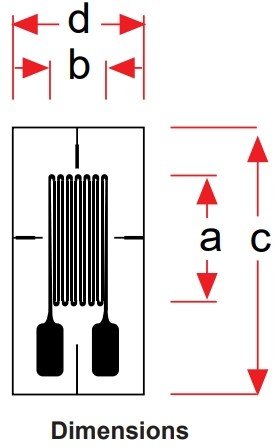

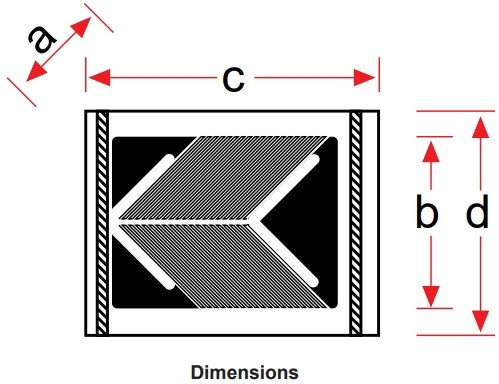

LY系列单轴应变片

带焊盘的封装应变片(附件终端焊盘用于应变消除和连接不同的应变片线)

传感器级应变计订货信息:

| 类型系列 | 型号(5件装) | FOIL MATERIAL | TEMP COEF.* | 尺寸mm(inch)† | MAX EXC | TERM PADS | ||||

| grid | carrier | |||||||||

| Ω | A | B | C | D | ||||||

| SG-3/350-LY47K | Karma | SS | 350 | 3.3 | 1.5 | 8.2 | 4.0 | 10 | TP-2 |

| SG-7/350-LY47K | Karma | SS | 350 | 6.3 | 3.9 | 12 | 7.8 | 15 | TP-3 | |

| SG-13/1000-LY47K | Karma | SS | 1000 | 13.0 | 5.0 | 23 | 10 | 17 | TP-3 | |

| SG-2/350-LY47 | Constantan | SS | 350 | 2.0 | 2.5 | 7.8 | 6.0 | 5 | TP-1 | |

| SG-3/350-LY47 | Constantan | SS | 350 | 3.8 | 1.7 | 7.0 | 6.0 | 10 | TP-2 | |

| SG-7/350-LY47 | Constantan | SS | 350 | 7.0 | 3.5 | 14.0 | 8.0 | 15 | TP-3 | |

| SG-13/350-LY47 | Constantan | SS | 350 | 12.5 | 5.0 | 23.0 | 10.0 | 17 | TP-3 | |

| 型号(10件装) | ||||||||||

| SG-2/350-LY41 | Constantan | CS | 350 | 2.0 | 2.5 | 7.8 | 6.0 | 5 | TP-1 | |

| SG-3/350-LY41 | Constantan | CS | 350 | 3.8 | 1.7 | 8.3 | 4.6 | 10 | TP-2 | |

| SG-7/350-LY41 | Constantan | CS | 350 | 7.0 | 3.5 | 14.0 | 8.0 | 15 | TP-3 | |

| SG-13/350-LY41 | Constantan | CS | 350 | 12.5 | 5.0 | 23.0 | 10.0 | 17 | TP-3 | |

| SG-2/350-LY43 | Constantan | ALUM | 350 | 2.0 | 2.5 | 7.8 | 6.0 | 5 | TP-1 | |

| SG-3/350-LY43 | Constantan | ALUM | 350 | 3.8 | 1.7 | 8.3 | 4.6 | 10 | TP-2 | |

| SG-7/350-LY43 | Constantan | ALUM | 350 | 7.0 | 3.5 | 14.0 | 8.0 | 15 | TP-3 | |

| SG-13/350-LY43 | Constantan | ALUM | 350 | 12.5 | 5.0 | 23.0 | 10.0 | 17 | TP-3 | |

附件端子焊盘

订购示例:SG-3/350-LY47K是五个单轴应变片的封装,带有Karma箔和封装焊盘,

“SS是与不锈钢相匹配的温度系数。(LY47)

"CS"是与碳钢匹配的温度系数。(LY41)

"明矾”是与铝相匹配的温度系数。(LY43)

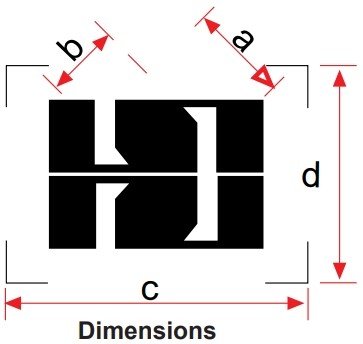

TY系列扭转应变花

带有四个焊盘的封装应变片(附件终端焊盘用于应变消除和连接不同的应变片线)

订货信息:

| 类型系列 | 型号(5件装) | FOIL MATERIAL | TEMP COEF.* | 尺寸mm(inch)† | MAX EXC | TERM PADS | ||||

| grid | carrier | |||||||||

| Ω | A | B | C | D | ||||||

| SG-5/1000-TY47K | Karma | SS | 1000 | 4.7 | 2.4 | 8.1 | 11.5 | 15 | TP-2 |

| SG-6/1000-TY47K | Karma | SS | 1000 | 5.7 | 11.5 | 3.8 | 8.6 | 15 | TP-2 | |

| SG-5/350-TY47 | Constantan | SS | 350 | 4.7 | 8.1 | 11.5 | 2.4 | 10 | TP-2 | |

| SG-6/350-TY47 | Constantan | SS | 351 | 5.7 | 3.8 | 8.6 | 11.5 | 11 | TP-2 | |

| SG-5/350-TY41 | Constantan | CS | 352 | 4.7 | 11.5 | 2.4 | 8.1 | 12 | TP-2 | |

| SG-6/350-TY41 | Constantan | CS | 353 | 5.7 | 8.6 | 11.5 | 3.8 | 13 | TP-2 | |

| SG-5/350-TY43 | Constantan | ALUM | 354 | 4.7 | 2.4 | 8.1 | 11.5 | 14 | TP-2 | |

| SG-6/350-TY43 | Constantan | ALUM | 355 | 5.7 | 11.5 | 3.8 | 8.6 | 15 | TP-2 | |

订购示例:SG-6/350-TY47是一个包含五个扭矩应变花的套装,带有两个Constahtan栅,封装有四个焊盘

*"SS"是与不锈钢匹配的温度系数。(TY47

”CS"是与碳钢匹配的温度系数。(TY41)

"ALUM"是与铝匹配的温度系数。(TY43)

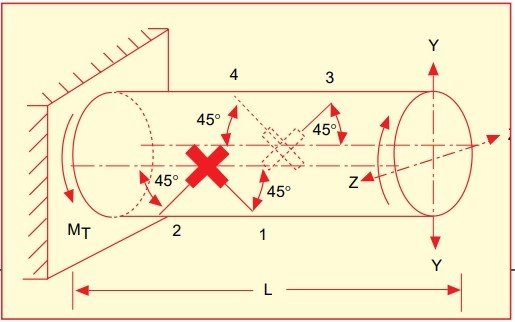

扭转应变

TY系列扭矩应变花

带有三个焊盘的封装应变片(附件终端焊盘用于应变消除和连接不同的应变片线)

订货信息:

| 图片 | 型号(5件装) | FOIL MATERIAL | TEMP COEF.* | 尺寸mm(inch)† | MAX EXC | TERM PADS | ||||

| grid | carrier | |||||||||

| Ω | A | B | C | D | ||||||

| SG-4/1000-TY37K | Karma | SS | 350 | 3.8 | 3.2 | 9.5 | 6.9 | 10 | TP-2 |

| SG-4/350-TY37 | Constantan | SS | ||||||||

| SG-4/350-TY31 | Constantan | CS | ||||||||

| SG-4/350-TY33 | Constantan | ALUM | ||||||||

订购示例:SG-4/1000-TY37K是一个包含五个扭矩计和两个Karma格栅的套装,封装在三个焊盘中

*"SS"是与不锈钢匹配的温度系数。(TY37)

“CS是与碳钢匹配的温度系数(TY31)

"ALUM"是与铝匹配的温度系数。(TY33)

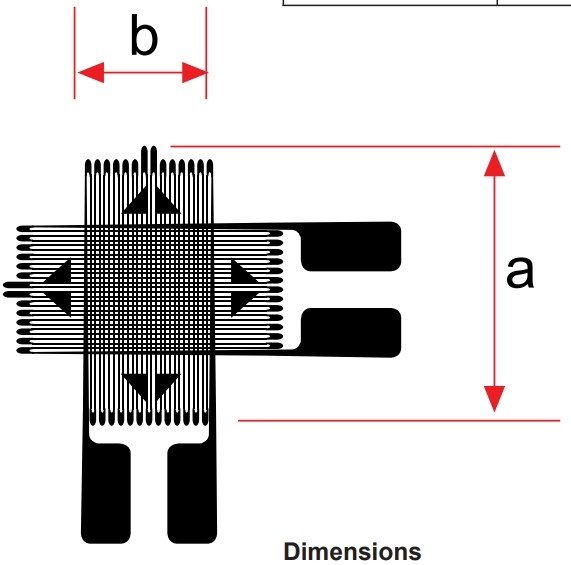

XY系列用于轴向应变的双轴应变花

带焊盘的封装应变片(附件终端焊盘用于应变消除和连接不同的应变片线)

订货信息:

| 图片 | 型号(5件装) | FOIL MATERIAL | TEMP COEF.* | 尺寸mm(inch)† | MAX EXC | TERM PADS | ||||

| grid | carrier | |||||||||

| Ω | A | B | C | D | ||||||

| SG-7/350-XY47K | Karma | SS | 350 | 3.0 | 2.8 | 8.0 | 8.0 | 10 | TP-2 |

| SG-7/350-XY47K | Karma | SS | 7.0 | 3.5 | 13.0 | 13.0 | 15 | TP-3 | ||

| SG-3/350-XY47 | Constantan | SS | 3.0 | 2.8 | 8.0 | 8.0 | 10 | TP-2 | ||

| SG-7/350-XY47 | Constantan | SS | 6.8 | 2.8 | 13.0 | 13.0 | 15 | TP-3 | ||

| SG-3/350-XY41 | Constantan | CS | 3.0 | 2.8 | 8.0 | 8.0 | 10 | TP-2 | ||

| SG-7/350-XY41 | Constantan | CS | 7.0 | 3.5 | 13.0 | 13.0 | 15 | TP-3 | ||

| SG-3/350-XY43 | Constantan | ALUM | 3.0 | 2.8 | 8.0 | 8.0 | 10 | TP-2 | ||

| SG-7/350-XY43 | Constantan | ALUM | 6.8 | 2.8 | 13.0 | 13.0 | 15 | TP-3 | ||

订购示例:SG-3/350-XY47K是一个由五个双轴应变片和两个Karma栅格组成的封装,封装有焊盘

"SS"是与不锈钢相匹配的温度系数。(XY47)

"CS"是与碳钢匹配的温度系数。(XY41)

"明矾”是与铝相匹配的温度系数。(XY43)

规格

箔厚:5μm

载体材料:聚酰亚胺

载体厚度:50μm

连接:焊盘(康铜量具);焊点(业力计)

标称电阻:350和1000欧姆

电阻容差:0.5%

标称值:2.0标称值(每个包装上印有实际值)

标称系数公差:1.0%

热性能

参考温度:23℃/73℉

工作温度:

静态:-30至250℃(-22至482℉)

动态:-30至300℃(-22至572℉)

温度特性:

碳钢:11 ppm/℃(6.1 ppm/℉)

不锈钢:17 ppm/℃(9.4 ppm/℉)

铝:23 ppm/℃(12.8 ppm/℉)

补偿温度:-5至120℃(5至248℉)

温度容差:1 ppm℃(0.5 ppm℉)

机械性能

至大应变:3%或30,000 μe

滞后:可忽略不计

疲劳(±1500 μe时):>10,000,000次循环

至小弯曲半径:3mm(1/8英寸

Copyright © 2004-2024 广州市赛拓仪器科技有限公司 备案号:粤ICP备07053378号-4

地址:广州市黄埔区崖鹰石路27号佳德科技园C栋301室 电话:020-85250202 邮箱:scitop@126.com

关注我们